Best quality products

Apna Anantha Farming Private Limited, an ISO certified Company (with ISO 9001:2015) is a registered Company having CIN as U01611JH2023PTC020352, GST as 20AAYCA5643E1ZP under the Companies Act, 2013 and having registered office address as the Flat No. 3A, Narayani Apartment, Road No. – 15, Patel Nagar, Hesag, Hatia, Ranchi -834003 and is represented by Smt. Kumari Bibha Sinha (mobile No. 7739648275) w/o Shri Indra Bhushan Prasad Sinha presently residing at the Qr. No. A/4, opposite Doranda Hospital, Doranda, Ranchi-834002, Jharkhand under the Doranda Police Station, Ranchi. Earlier it was Ananta Farming, a registered partnership firm. It is registered with the Registrar of Firms, Jharkhand, Ranchi and is having registration number as 230 /2020 and its registered office at the flat No. 3A, Narayani Apartment, Road No.15, Patel Nagar, Hesag, Hatia, Ranchi, Jharkhand – 834003.The Firm is registered to carry out the business of agriculture and processing of food items/cereals/fruits/flowers along with agriculture and processing of aromatic/herbal/medicinal/flower plants, extraction of oil there from, sale of oil and the other items obtained there from, preparation, processing and sale of compost/manure etc. by acquiring land – plots on lease/contract etc.

The Company, Apna Anantha Farming Private Limited has hired a flat of about 1656 sq.feet super built-up area at the Road No.15, Patel Nagar, Hesag, Hatia, Ranchi, Jharkhand – 834003 for its official purposes. It has also acquired about 120(one hundred and twenty acres) of agriculture land on lease or rent at village chukru, Panchayat – amma, Post – Amma pakna, Thana – Torpa, Thana No. 90, District – Khunti, Jharkhand. The objective of the Company is to carry out the business of aromatic/herbal/medicinal/flower plants, extraction of oil there from, sale of oil and the other items obtained there from, by acquiring land–plots on lease/contract etc. and by establishing plants, machinery, factories etc. thereon. The Company has planted lemon grass/Moringa plants on the entire available land of about 120 acres.The entire land of about 120 acres is having drip irrigation facilities. The Company, at present is having two electrical transformers of its own, seven electrical connections for agricultural purposes, four deep tube wells borings , two big wells and all these six water points are equipped with required machineries and all of them in separate six rooms.The Company is having a Mahindra tractor with dala and hala, a Mahindra’s Bolero pick up 3T, A drone of 35 litres capacity to sprinkle pesticides, insecticides etc., a 15 KW Mahindra Generator, water storage tanks of more than 15000 litre capacity and the entire land of 120 acres is having electricity, a distillation plant of sufficient capacity for extraction of lemon grass oil, big sheds for storing cut plants/grasses and rooms for official/staying purposes. The Company is having arrangements of 24 hours work on its land and about 60 to 70 workers generally work on its land. The Company is the only agriculture company in Jharkhand, India which is having drone of its own for agricultural purposes. The Company is havingUS Patent as 7,678,429/6cr, GMP as,A/68799:2015,TUV as ISO:0126:2015, US Custom Border Protection Protocol as 78/780 Ananta/15 lacs, FCC as A/A/F/770011:ISO:2015, SIF fA680/26:77, OPS as 8765410066 and 2918273654 FSCS as 777017293 etc. The Company has planned to acquire 200 acres more land for lemon grass and moringa farming and to enhance its distillation capacity very shortly.

The Company, Apna Anantha Farming Private Limited, at present is having only two Directors namely Smt. Kumari Bibha Sinha and Shri Rajesh Kumar. Smt. Sinha is authorized to make transactions and correspondences with the Bank and to sign documents relating to contracts, agreements, sale, purchases, receipts, payments etc. with any person/institution/firm/company/offices/departments on behalf of the Company.

Smt. Kumara Bibha Sinha (Mobile No.7739648275) is the wife of Shri Indra Bhushan Prasad Sinha, a Class –1 officer, designated as Sr. Audit Officer in the O/o Principal Accountant General (Audit) Jharkhand, Ranchi. She is residing presently in a quarter (Qr.No. - A/4, Opposite Doranda Hospital, Doranda, Ranchi- 834002, Jharkhand) allotted by the employer of her husband. She is already engaged in business of real estate and working as one of the two partners in the Partnership Firm namely M/s Maa Bhagwati Developers, Ranchi, wherein also she is the authorized signatory of the Firm. The said Firm has constructed two Apartments at the Road No.15, Patel Nagar, hesag, Hatia, Ranchi - 834003 in the name of Narayani Apartment and Satya Apartment and no case has so far been filed against her or against the said Firm in any court or with the police by the land owners or the customers or the suppliers etc. relating to the said two firms. No due return either the Income Tax-return or the GST is pending for filing by the Firm and the Firm at present is having two more Apartments to construct, in which the Firm is having an investment of about Rs. one crore. Further the Firm, at present is having four flats to book and sale. Smt. Sinha is filing I-Tax returns regularly.

Rajesh Kumar, the another partner of the Firm is also engaged in business of real estate and working as one of the two partners in the Partnership Firm namely M/s Maa Bhagwati Developers, Ranchi. He also owns a proprietorship Firm in the name and style of M/s Rajesh Kumar Gupta at 5/2C, Majlish Ara road, Mini Park, Kolkata and filing I-Tax return regularly. He is presently residing in his own double storied building at the Road No.-05, Hawai Nagar, Birsa Chowk - Khunti Road, Ranchi -834003, Jharkhand, India.

Lemon grass is a perennial crop and having oil production for 5 years once planted. Lemon grass plants are hardy and grow under a variety of conditions. The most ideal climatic condition is a warm and humid climate with plenty of sunshine. It can be grown in poor, hardy and even rocky soils and also in the hill slopes. It smells sweet and has a fresh, lemony aroma with a citrus flavor. It is a common ingredient in Thai cooking and a bug repellant. Lemon grass oil is anti-bacterial, anti – oxidant, anti-inflammatory, anti-fungal and anti-cancer too. It contains high levels of an aromatic tarpene known as linalool which is said to be as effective as chemo in targeting cancer cells. Lemon grass oil is used in aroma therapy to freshen air, reducing stress and uplifting mood. It is also used as a folk remedy to promote sleep, relieve pain and boosting immunity. It may reduce cancer risk of a person if taken properly. The citrola in lemon grass is thought to have potent anti-cancer abilities against some cancer cell lines. A 2009 study published in the journal namely “Chemico-Biological interactions” revealed that lemon grass essential oil is effective in targeting at least 12 different human cancer cell lines. Animal trials showed that direct injection of lemon grass essential oil inhibited cancer tumors.

| Plant name | Lemongrass |

| Species | Cymbopogon Flexuosus |

| Family | Poaceae |

| Part used in Lemongrass | Oil extracted from leaves and stems |

The essential oil of this plant which contains chemical compounds neral and citral is valued for its fragrance and for a number of traditional medicinal and household uses.

Some popular varieties include Sugandhi (OD-19), Pragati, RRL - 16 , PRC-1, CKP-25, CIM Krishan and CIM Sikhar

Lemongrass well grows in loamy soil with PH range 5 to 8. It is a tropical plant and its growing period requires abundant sunshine. We avoid frost prone area for its cultivation because of its sensitivity to frost condition.

Ideal condition requirement for cultivation of lemongrass

| Elevation | Up to 300 meters |

| Annual Rainfall | 700-3000mm |

| Ideal temperature | 15-38 degree centigrade |

Lemongrass can be grown in heavy fertile soil to poor sandy loams; it can be grown in wide variety of soils. The ideal pH range for its cultivation is 5 to 7.5. It can maximum tolerate pH of 9.5. Soil with water logging results in poor yield and less oil. So it thrives best in well drained loamy soil.

Lemongrass can only be propagated through slips (saplings). Healthy treated slips at least 2 years old are the best choice for commercial farming. It is in good practice to use at least two year old slips for propagation.

We plow the land 2-3 times by using tractors until the soil becomes fine-tilth because by doing so, it gives better aeration. Unwanted plants or weeds should be removed. After putting the manure, the land should be laid into beds .To avoid water stagnation trowel and level the field. Lemongrass slips should be sown directly (40-50 mm insertion). We get lemon grass transplanted into the field during rainy season. Established healthy seedling or slips of 20-50 cm long should be planted during rainy season having distance in row of 50-60 cm apart with plant distance of 50-60 cm within the row. Lemongrass slips or saplings should be planted firmly not very deeply in the soil.

To avoid transplantation shock, transplanting is preferred in evening hour. Light irrigation is preferred after transplanting .Within 10-12 days of planting, gap filling should be done. To avoid mortality rate, it is preferred to plant 2 slips /seedling .The optimum sapling rate per hectare is 45000

To get more yield, irrigation should be at right stage. Lemongrass can be grown at both condition as rain-fed crop or under irrigated conditions .Flood irrigation is best suited for this crop .The irrigation frequency depends on climatic conditions and soil moisture holding capacity .In hot and dry climate , it requires irrigation at 10-12 days interval .Stop irrigation 7 to 8 days before harvesting the grass.

Farmyard manure of 10 tons/ha (applied during land preparation) and NPK 20:50:40 kg/ha .Top dressing should be done with "N"(nitrogen) of 15 kg /ha in 3 intervals, which should be 3, 6 and 9 month after planting.

Following pests and diseases are found in Lemongrass cultivation -

Pests:

White grubs, Aphids, Thrips and termites are the common pest found in Lemongrass cultivation.

Control Measure :

White grubs and termites are controlled by flood irrigation, water kills these pests. Thrips and Aphids controlled by spraying Azadirachtin 1 %( 10,000 ppm) @5ml/lit water.

Diseases : -

Curvularia blotch and Ellisiella blight diseases can be controlled by foliar application of Bordeaux mixture 1% of 2 weeks interval at initial stage of disease attack.

The Location: The site for the project has been selected after very careful observation of various factors . The availability of correct cultivation area, electricity, manpower are the advantages of this site at Chukru,Block Torpa,Khunti.

The promoter, Apna Anantha Farming Private Limited (mobile No. – 7739648275/7903434046) is well versed with the required plant & machinery, implements & Manufacturing process. The unit has already procured the necessary plants & equipment of high quality for manufacture of quality products which is further helping the unit in establishing the product in the market.

The raw materials required for this project are the Aromatic Plants Leaves which are in abundance with the promoter, M/s Ananta Farming.

The auxiliary systems required for lemon grass farming are distillation plants or units, water pumps, D.G sets, electrical connections, equipments / appliances, testing and laboratory equipments, weighing machines, General Tools & implements, agriculture equipments etc. and the promoter, Apna Anantha Farming Private Limited (mobile No. – 7739648275/7903434046) is having all these.

There are large numbers of different essential oils can be processed which can be manufactured but at present the company has decided to concentrate on the Lemongrass oil and related products. This company will manufacture various products as per the market demand in future.

The promoter, Apna Anantha Farming Private Limited (mobile No. – 7739648275/7903434046) is having all kinds of Technocrats, Managers, Technicians, skilled/ unskilled staff and we are guided by professional consultants/scientists. A Practical and scientific approach will be adopted for the project implementation. A bar chart will be drawn making proper interaction of the various activities and every care will be taken to avoid time overrun and the cost overrun as well.

The company's site location at Torpa, Khunti, which is such that manpower is not a problem.

Promoter has been setup with the only moto to produce aromatic oil items of the best quality and induce new ideas and effectiveness at a comparatively low priced for the benefit of the masses. The company is having about 120 acres of land to cultivate moringa/drumstick and lemon grass and extract lemongrass oil there from.

It should be harvested at right stage for high oil yield. Crops gets ready within 3-6 month after planting .Harvesting should be carried at an interval of 3-4 months and up to 5 years. Cutting of grass should be done by leaving 15 cm from the ground level. Keep the grass in shade for 3-4 days after harvesting. Then send it to steam distillation for oil extraction.

For good practice, it is advised to use wilt grass for 24 hr at least. Wilting allows the larger quantity of grass to be packed, due to wilting, moisture content gets reduced and more oil can be extracted, thus economizing the fuel use.

The equipment for steam distillation consists of a boiler to produce steam, a condenser, 1 to 3 separators and a distillation tub. The distillation tub is made up mild steel or stainless steel, and perforated bottom over which grass rest. Steam inlet pipe at the bottom of the tub. A removable lid is fitted on the top .Loading and unloading can be done in perforated cage with iron chains, which can be lowered in the container with the help of chain-pulley .varieties of condenser are available, but tubular condenser are best among them .The condenser is having one inlet and one outlet by which cold water is made to flow through the chamber to cool the pipes ,when the distillate flow through them .

It is preferred to use chopped grass into shorter length ,to obtain the maximum yield of oil and to facilitate the release of oil, further advantage of chopping grass is that more grass can be charged into the container .The steam is allowed to pass into the container with the steam pressure from 1.5 to 2 kg in the boiler .The mixture of water and lemongrass oil passes into the condenser .The distillate collects in the separator as the distillation process goes on .As the oil is lighter than water and insoluble floats on the top of the separator and continuously drawn off, Lemongrass Oil is then filtered

Many factors depends on the yield of the crops ,factors like cultivar, plant age , soil , irrigation , climate and cultivation practice. However an average yield of 50 - 65 tons/ha/year can be obtained under ideal conditions. 220-250 kg /ha may be obtained from 2nd year in case of well irrigated crops. Oil yield is low in first year, thereafter oil yield increases and gradually decreases after 4th year.

Plantation in 01 acre of land - 15000 plants,

Planting period---------- june- august & February-March.

Cutting period—-------- 90-100 days and thereafter 70-90 days.

| Head | 1 st six month | 9 th month | 12 th month | 2 nd year | 3 rd year | 4 th year | 5 th year |

| Land Preparation | 5,000 | ------- | ------- | ------- | ------- | ||

| Plants purchase cost/15,000 plants | 30,000 | ------- | ------- | ------- | ------- | ||

| Layout | 2,000 | -------- | -------- | -------- | -------- | ||

| Fertilizer | 2,000 | 2,000 | 2,000 | 8,000 | 10,000 | 10,000 | 15,000 |

| Irrigation | 5,000 | 5,000 | 5,000 | 20,000 | 25,000 | 25,000 | 30,000 |

| Agricultural work | 5,000 | 5,000 | 5,000 | 20,000 | 25,000 | 25,000 | 30,000 |

| Land-rent | 5,000 | --------- | --------- | 6,000 | 7,000 | 8,000 | 9,000 |

| Cutting/storing | 3,000 | 3,000 | 3,000 | 12,000 | 15,000 | 15,000 | 20,000 |

| Processing | 4,000 | 4,000 | 4,000 | 16,000 | 20,000 | 20,000 | 25,000 |

| Total expenditure. | 61,000 | 19,000 | 19,000 | 82,000 | 1,02,000 | 1,03,000 | 1,29,000 |

| Oil production | 70 kg. | 100kg. | 100kg. | 400kg. | 5,00kg. | 400kg. | 400kg. |

| Sale rate of oil | 1200/kg. | 1200/kg | 1200/kg | 1200/kg | 1200/kg | 1200/kg | 1200/kg |

| Sale price | 84,000 | 1,20,000 | 1,20,000 | 4,80,000 | 6,00,000 | 4,80,000 | 4,80,000 |

| Net profit | 23,000 | 1,01,000 | 1,01,000 | 3,98,000 | 4,98,000 | 3,77,000 | 3,51,000 |

NOTE: - Plant once planted shall work for 05 years and thereafter we shall plant them again and the oil production and expenditure incurred shall be in the same process. We have taken the sale rate of oil as the fixed rate of Rs.1200/- per kilogram, but that may change as per the demand and production.

The Project has been proposed to set up in the name and style of M/s Ananta Farming. The unit is going to be a Distillation unit to manufacture essential oil. Hydrosol, deoiled grass compost and other related items. Being enthused and impressed by the success of the guidelines of the Industrial policy and the conductive industrial environment of the state , the promoter is an educated and experienced person and has the zeal and capacity for setting up the unit. The proposed site is a completely pollution free area in the lishgreen valley of the road with river bank. There is no such unit in the area. Therefore, realizing the need for such a project, the promoters have decided to set up the unit.

The Promoters have observed certain vital points based on the feedback received from the market. The need for this project arises from the market response, established demand and their future projections with the massive activity and awareness for the essential oils going on, The requirement of day to day health care of the human beings, observing the various facts and considering the vast scope, this segment of industry offers, the promoters of the industry have decided to set-up the unit which will care to the needs of large section of society.

Aromatic industry has been playing a critical role in the earth eco system. Present day cosmetic industry has become highly dependent on various essential oils, as these have become indispensable natural items for beauty professionals, mainly for various skin treatment and beautification therapy. Also various FMCG products likes soap, shampoo, hand wash is using essential oils to provide skin friendly organic product. There are several factors driving the growth of this market in India. Due to the advantage of natural ingredients and no side effects, essential oils are preferred over synthetic aromatic oils. With the current general trends towards naturals and herbals types of products, the demand for these oils is increasing at very fast rate. An easy growth of these raw material grasses in the state of Jharkhand makes the area a choice place for setting up such units.

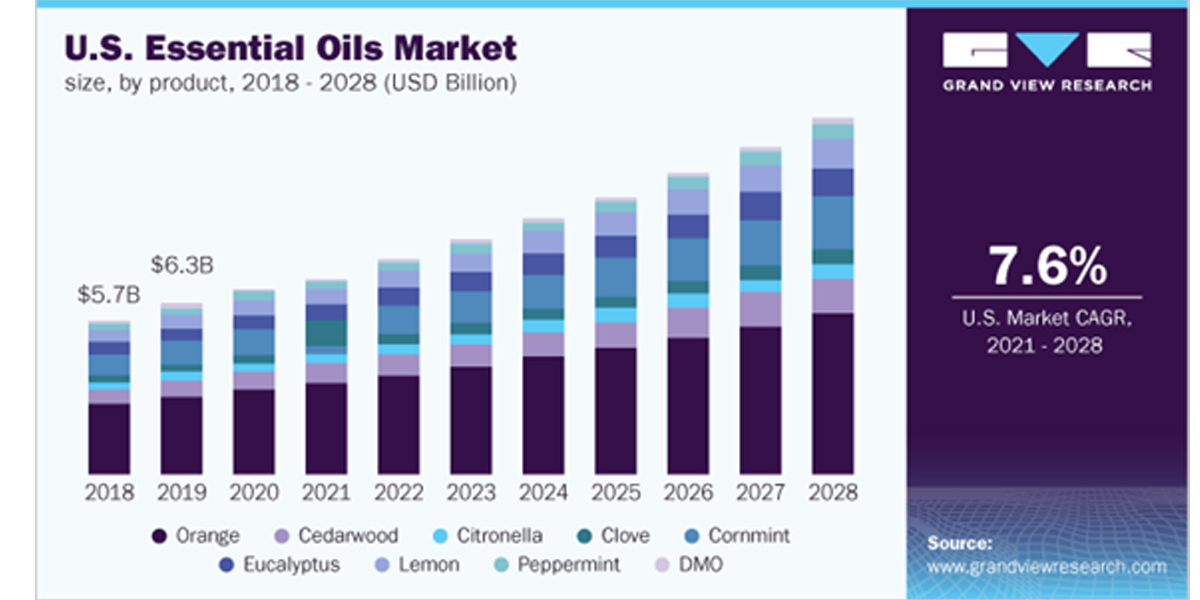

The market potential in India and abroad include the driving forces that are creating the demand for Essential oils and contributing to an increased demand for these products. The global essential oils market size was valued at USD 18.6 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 7.4% in terms of revenue from 2021 to 2028. The market is expected to be driven by increasing demand from major end-use industries, such as food and beverage, personal care and cosmetics and aromatherapy. Unlike most conventional medicines and drugs, essential oils have no major side effects. Such traits of the product are projected to be the major driving factor for market growth.

In the very initial stage the products will be marketed through various existing dealers and distributors dealing with the same products. Only some sales person from our organization will be employed in the state of north east India to promote our products. In Ranchi, Hazaribagh, Bokaro, Chatra, Dhanbad, Jamshedpur, the unit will appoint its own sales personnel for business promotion and dealers & distributors to deal in its products. It is hoped that almost 70 - 80% of our initial output can be marketed in and around Jharkhand itself. We have also planning that after the commencement of full fledged production and inauguration in market, we will establish our own marketing division by employing efficient personnel to capture the major share in the domestic market.

Drumstick/Moringa is referred to as the “miracle tree” because of its wide range of nutritional, medicinal and purifying properties. It is also called a ‘super food” because of its awesome potential to improve health and eliminate hunger around the world. It has high amounts of protein and is significant source of vitamins and minerals. The leaves of the Drumstick/moringa tree contain 18 amino acids, 08 of which are essential amino acids, making them a “complete protein”. It is full of phyto-nutrients and disease fighting antioxidants. The scientific name of drumstick tree is ‘Moringa Oleifera’ belonging to the family Moringacea and the drumstick tree is popularly known as the moringa/horseradish/benzoil/sahjan/sutti tree due to its various qualities. The tree is called moringa due to its long, slender, triangular seed pods, horseradish’s name falls due to the drumstick roots taste resembles the taste of horseradish and it is called benzoil tree due to extraction of benzoil oil from moringa seeds. Drumstick/Moringa is a vegetable that is grown for its edible pods, leaves and flowers. Drumstick/Moringa vegetables are rich in nutrients, high in calcium and water contains antioxidants. Drumstick/Moringa taste like beans but are a bit sweeter, mostly used in ‘Sambhar’ a popular South Indian Recipe.

Drumstick/Moringa trees are grown in tropical and subtropical regions throughout the world. Drumstick/Moringa tree, a fast – growing perennial vegetable tree has a drought-resistant capability.

Drumstick/Moringa tree, a medium size tree of 10 to 12 meters in height, having trunks about 35 cm to 45 cm in girth or diameter consisting of thick corky fragile stems. Drumstick/Moringa tree branches usually seem to droopth leaves and leaflets,whereas the drumstick pods are long, pendulous in shape with the length of 20 cm to 80 cm. Moringa tree bears bisexual flowers of yellow, creamy and white colour with sweet fragrance and seeds are trigonous in shape. Drumstick/Moringa tree starts wearing parts after 06 months of the plantation. Drumstick/Moringa pods have distinct flavours and are very popular, especially in South Indian cuisine.

Drumstick/Moringa farming varieties are classified into two types-

Paranniel types- This type of cultivation has been practiced for centuries but this type is not preferred for commercial drumstick/moringa farming because it takes longer time to grow and further they require greater rainfall and are less resistant to pests and disease. This type of cultivation is usually practiced through the drumstick/moringa cuttings.

Annual types- This type of drumstick/moringa cultivation is preferred for commercial farming and India is the largest producer of drumstick/moringa in the world. These types are propagated through seeds and are fast growers that reach maturity in less time. They are also capable of adapting to various soil and different climate conditions. Early maturity, higher yield and fast growing are the specific features of this type of drumstick/moringa.

The varieties of drumstick/moringa are – PKM1, PKM2, Chavakachcheri, chem. Murungai, Kudumiyanmalai1 (KM-1), Mulanur Moringa, Valayapatti Moringa and ODC. ODC is the latest moringa variety which is being mostly used in current farming.

Drumstick/moringa water requirement: - They do not want much water and thereby they reduce the cost of Drumstick/moringa farming. Drumstick/moringa plants/ trees need very less water and can easily survive in drought conditions for about 06 months. Too dry and too wet soils may result in flower shredding. The irrigation cycle should be as below:-

Substantial soil moisture levels should be maintained during the flowering period and water stagnation should be avoided in Drumstick/moringa farms.

Drumstick/moringa farming/cultivation requires 02 times deep ploughing. Last ploughing requires farmyard manure (FYM) mixed with soil. Drumstick/moringa soil mix for putting in pits prepared for planting requires 10-15 kg FYM/vermi compost + 100 gm nitrogen + 200 gm phosphorous + 50 gm potassium.

Pits size for green leaves- spacing in – between plants 3-4 feet, depth- up to 01feet,

Pits size for pods- spacing in – between plants 10-15 feet, depth- up to 1.5 feet.

(First put the prepared soil - mix in the lower part of the pits and then plant DRUMSTICK/MORINGA plants in the pits and mix extra soil as per requirement).

We, for early germination and in order to increase Drumstick/moringa yield, practice the moringa seed treatment more carefully. We, to control seed borne diseases, treat the seed with approved bio-pesticides or chemicals before sowing. We soak the seeds with approved bio-pesticides or chemicals for a full night and sow them another day in the early morning. We, for increased seed vigour and growth, treat about 650 gms of seed with 100 gm azospirillum. Sulphur and neem oil spray is also used in the Drumstick/moringa seed treatment process.

Drumstick/moringa fertilizer for plants is classified according to the stages:-

After 03 months of Drumstick/moringa seed sowing – Urea (100gm) + Superphosphate (100gm) + Muriate of Potash Fertilizer (50gm) is applied to each pit or plant,

During Drumstick/moringa flowering season- Urea (100gm) to each pit or plant,

Drumstick/moringa fungicide – Mancozeb fungicide (M-45)is applied especially during flower blooming and then it will prevent flower drop during first rain after flowering.

A monthly two-time fungicide spray is necessary to get rid of Drumstick/moringa pests and diseases.

Drumstick/moringa stem cutting propagation method is used for perennial cultivation due to suitability. This practice is done when a Drumstick/moringa tree stops producing pods. Cutting the branches for propagation will also result in the fresh growth of the used tree. First select the healthy Drumstick/moringa tree and then cut the branches with 120- 150 cm in length and 5-12 cm in diameter. Place one-third part of the Drumstick/moringa branch cut inside the pit and apply cow dung at the top end of the cut branch. This will protect the cuttings from pests and disease.

Bud worm(Noorda Moringa),

Lead Caterpillar(Noordablitealis),

Hairy Caterpillar(Eupterotemollifera),

Pod fly (Gitona Distigma),and

Bark caterpillar(Indarbela Tetraonis)

Drumstick/moringa pod production, 1st year-------------- 10 to 12 tonnes,

Drumstick/moringa pod production, 2nd year onward --------- 12 to 17 tonnes,

Drumstick/moringa leaves production, 1st year--------------------- 08 to 10 tonnes,

Drumstick/moringa leaves production, 2nd year onward -------------- 10 to 15 tonnes,

Drumstick/moringa leaves-powder production, 1st year-------------- 1.0 to 1.5 tonnes,

Drumstick/moringa leaves-powder production, 2nd year onward --------- 1.5 to 3.0 tonnes,

1. (A) Drumstick/moringa annual costing per acre, if farming for pods

| # | Items of annual expenditure | Costing during 1 st year | Costing during 2 nd year | Costing during 3 rd year | Costing during 4 th year | Costing during 5 th year | Costing during 6 th year | Costing during 7 th year |

| i. | Seed cost | 5,000 | ----------- | ----------- | ----------- | ----------- | ------------- | --------------- |

| ii. | Land preparation | 10,000 | ----------- | ----------- | ----------- | ----------- | ------------- | -------------- |

| iii. | Labour cost | 30,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 |

| iv. | Manure & fertilizer | 10,000 | 11,000 | 12,000 | 13,000 | 15,000 | 17,000 | 20,000 |

| v. | Irrigation | 17,000 | 20,000 | 22,000 | 25,000 | 30,000 | 35,000 | 40,000 |

| vi. | Plant protection | 12,000 | 15,000 | 17,000 | 20,000 | 25,000 | 30,000 | 35,000 |

| vii. | Miscellaneous charges | 15,000 | 17,000 | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 |

| viii. | Total annual cost | 99,000 | 88,000 | 1,01,000 | 1,18,000 | 1,40,000 | 1,62,000 | 1,85,000 |

1(B) Profit per acre, if farming for pods:-

| year | Quantity annually produced | Sale rate of pods per kg in Rs. | Sale price of pods in Rs. | Costing | Profit |

| 1st year | 10,000 kg | 20 | 2,00,000 | 99,000 | 1,01,000 |

| 2nd year | 11,000 kg | 22 | 2,42,000 | 88,000 | 1,54,000 |

| 3rd year | 12,000 kg | 25 | 3,00,000 | 1,01,000 | 1,99,000 |

| 4th year | 13,000 kg | 27 | 3,51,000 | 1,18,000 | 2,33,000 |

| 5th year | 14,000 kg | 30 | 4,20,000 | 1,40,000 | 2,80,000 |

| 6th year | 15,000 kg | 32 | 4,80,000 | 1,62,000 | 3,18,000 |

| 7th year | 16,000 kg | 35 | 5,60,000 | 1,85,000 | 3,75,000 |

| Profit in 7 years | 16,60,000 |

2(A) Drumstick/moringa annual costing per acre, if farming for leaves:-

| Sl.No. | Items of annual expenditure | Costing during 1 st year | Costing during 2 nd year | Costing during 3 rd year | Costing during 4 th year | Costing during 5 th year | Costing during 6 th year | Costing during 7 th year |

| i. | Seed cost | 15,000 | ----------- | ----------- | ----------- | ----------- | ----------- | ----------- |

| ii. | Land preparation | 10,000 | ----------- | ----------- | ----------- | ----------- | ---------- | ----------- |

| iii. | Labour cost | 60,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 55,000 |

| iv. | Manure and fertilizer | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 |

| v. | Irrigation | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 55,000 |

| vi. | Plant protection | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 |

| vii. | Miscellaneous charges | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 55,000 | 60,000 |

| viii. | Total annual cost | 1,80,000 | 1,45,000 | 1,70,000 | 1,95,000 | 2,20,000 | 2,45,000 | 2,70,000 |

2(B) Profit per acre, if farming for leaves:-

| year | Quantity annually produced per acre in kg | Sale rate of leaves per kg in Rs. | Sale price of leaves in Rs. | Costing | Profit |

|---|---|---|---|---|---|

| 1 st year | 8,000 | 30 | 2,40,000 | 1,80,000 | 60,000 |

| 2 nd year | 8,500 | 32 | 2,72,000 | 1,45,000 | 1,27,000 |

| 3 rd year | 9,000 | 35 | 3,15,000 | 1,70,000 | 1,45,000 |

| 4 th year | 9,500 | 37 | 3,51,500 | 1,95,000 | 1,56,500 |

| 5 th year | 10,000 | 40 | 4,00,000 | 2,20,000 | 1,80,000 |

| 6 th year | 10,500 | 42 | 4,41,000 | 2,45,000 | 1,96,000 |

| 7 th year | 11,000 | 45 | 4,95,000 | 2,70,000 | 2,25,000 |

| Profit in 7 years | 10,89,000 |

3(A) Drumstick/moringa annual costing per acre, if farming for leaves powder

| # | Items of annual expenditure | Costing during 1 st year | Costing during 2 nd year | Costing during 3 rd year | Costing during 4 th year | Costing during 5 th year | Costing during 6 th year | Costing during 7 th year |

|---|---|---|---|---|---|---|---|---|

| i. | Seed cost | 15,000 | ----------- | ----------- | ----------- | ----------- | --------- | --------- |

| ii. | Land preparation | 10,000 | ----------- | ----------- | ----------- | ----------- | ---------- | ---------- |

| iii. | Labour cost | 60,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 55,000 |

| iv. | Manure and fertilizer | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 |

| v. | Irrigation | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 55,000 |

| vi. | Plant protection | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 |

| vii. | Miscellaneous charges | 1,00,000 | 1,25,000 | 1,30,000 | 1,35,000 | 1,40,000 | 1,45,000 | 1,50,000 |

| viii. | Total annual cost | 2,50,000 | 2,35,000 | 2,60,000 | 2,85,000 | 3,10,000 | 3,35,000 | 3,60,000 |

3(B) Profit per acre, if farming for leaves powder:-

| year | Quantity annually produced in kg | Sale rate of leaves powder per kg in Rs. | Sale price of leaves powder per kg in Rs. | Costing | Profit |

|---|---|---|---|---|---|

| 1 st year | 1,000 | 500 | 5,00,000 | 2,50,000 | 2,50,000 |

| 2 nd year | 1,125 | 525 | 5,90,625 | 2,35,000 | 3,55,625 |

| 3 rd year | 1,250 | 550 | 6,87,500 | 2,60,000 | 4,27,500 |

| 4 th year | 1,375 | 575 | 7,90,625 | 2,85,000 | 5,05,625 |

| 5 th year | 1,500 | 600 | 9,00,000 | 3,10,000 | 5,90,000 |

| 6 th year | 1,625 | 625 | 10,15,625 | 3,35,000 | 6,80,625 |

| 7 th year | 1,750 | 650 | 11,37,500 | 3,60,000 | 7,77,500 |

| Profit in 7 years | 35,86,875 |

Important varieties of moringa/Drumstick are- Moolanur, Valayapatti, Chavakacheri, Chemmurungai, Kattumurungai, Kodikkalmurungai, Palmurungai, Punamurungai and palamedu .The Horticulture College and Research Institute of Tamil Nadu Agriculture University, Periyakulam has succeded in developing seed propogated moringa types, which has revolutionized the moringa cultivation in the country. It has released two improved annual moringa varieties i. e. Periyakulam-1(PKM-1) and Periyakulam-2(PKM-2) for commercial cultivation. Other annual types of Moringa/drumstick are KM-1 and Dhanraj.

The annual Moringa is propagated through seeds and the seeds are directly dibbled in the pit to ensure accelerated and faster growth of the seedlings. The best suited season for sowing the seeds is September. An espacement of 2.5X2.5 m is adapted with a population of 1600 plants per hectare. The seed germinates 10 to 12 days after sowing. The pre-sowing seed treatment of Moringa with azospirillum cultures at the rate of 100 gm per 625 gm of seeds results in early germination, increases seedling vigour, growth and yield.

It comes to flowering within 5-6 months of sowing and comes to harvest in 7-8 months. The peak harvest is during March-August. The plants grow to a height of 4-6 mt. in a year and produce 6-12 primary branches. The pinnate leaves are about 40 cm long with small leaflets which are dark green on the upper side and pale green on the lower side. Though the flowers are in clusters of 25-150 per cluster, only one pod develops usually and rarely 2-4 develop per cluster. The pods are 75 cm long with a girth of 6.3 cm and weight 150 gm with 70% flesh.

When the terminal bud on the central leader stem attains the height of about 75 cm(two months after sowing),it is pinched, which promotes the growth of many lateral branches and reduce the height of the tree.

In annual moringa, when the harvest is over, the trees are cut down to a height of one metre above ground level for ratooning. These ratoon plants develop new shoots and start bearing four or five months after ratooning. Three ratooning operations are recommended during the production cycle. During each rationing operation, the plants are supplied with the recommended level of N, P and K nutrients along with 20-35 kg of Farm yard manure.

The annual moringa types are seasonal in terms of fruit-bearing and the crop sown during September comes to harvest within six months. Fruits of sufficient length and girth are harvested before they develop fibre. The harvest period extends for 2-3 months and each tree bears about 250-400 fruits/year/tree.

Intensive moringa leaf production can be obtained by planting at 10 x 10 cm density with sufficient fertilizer. The green matter is harvested when plants reach a height of about 50 cm or more (every 35 to 40 days).The branches are cut up to a distance of 15 to 20 cm above the ground. Although losses of seedlings may occur up to 20-30 % in the first year, the vigorous re- growth of the remaining seedlings produce 3-5 new shoots after each cutting. Harvest up to nine times can be obtained annually. A yield of 650 metric tonnes of leaf yield can be obtained in sandy and well drained soil.

The moringa tree has a compound leaf and one leaf is made up of multiple leaflets. Manual harvesting of shoots and leaves with a pair of shears, a sickle or a sharp knife is recommended. All shoots should be cut at the desired height i. e. 30 cm to I m above ground. Mechanical harvesting could also be used for large-scale, intensive leaf production. The produce should be harvested at the coolest time of the day i. e. early morning or late in the evening. It is important to make sure that there is no dew on the produce before harvesting, especially in the morning to avoid rot during transportation.

The pods are harvested mainly between March and June. A second crop is normally harvested from September to October. Fruits of sufficient length and girth are harvested before they develop fibre. The harvest period extends for 2-3 months and each tree bears 250-400 fruits depending on the type. The pods are harvested when they are young, tender and green. They are eaten as green beans. Older pods are fibrous and develop a tough shell, but their pulp and immature seeds remain edible until shortly before the ripening process begins. Immature seeds can be used in recipes similar to green peas. Fresh or dried flowers are used for making tea.

The pods, for seed, should be harvested as early as possible when they reach maturity i. e. when they turn brown and dry. Fruits should open easily. Seeds are extracted, bagged and stored in a dry place.

Harvesting of brown coloured moringa fruits at 20 days after anthesis leads to recovery of good quality seeds with high germination potential. Black followed by brown coloured seeds are superior with higher seedling quality than white seeds. Harvested pods must be dried for 1-2 days under shade with good ventilation. The seeds are extracted manually by opening the pods using gentle pressure on them. On opening, the seeds are separated freely. Small, shriveled and damaged seeds are removed. Annual moringa seeds can be stored for up to 12 months. Freshly harvested seeds are dried to 8% moisture content and treated with captan @ 2gm/kg of seeds and packed in 700 gauge polythene bags. The black and brown seeds treated with carbendazim 2gm/kg of seeds and stored in 700 gauge polythene bags maintains more than 84 % germination up to 12 months.

Leaves are washed in fungicide (benlate500ppm) prior to storage. The cooling method is hydro cooling and the storage method is cold storage. The lowest physiological loss in weight (PLW) is recorded in fruits, if packed in polythene bags followed by corrugated fibre board boxes with coir waste as filling material. The highest carotene and ascorbic acid contents are found in fruits packed in polythene bags. Leaves and flowers may be dried in the shade or dehydrated and then pounded or ground and used as a food additive to improve protein content of food. Leaves and flowers are also used for tea.

Fresh moringa leaves, transported loosely, should be well ventilated. For shorter distances aerated baskets or perforated plastic containers should be used to transport the fresh leaves. Transportation should be during the cooler parts of the day i. e. early morning, evening or night. Leaves being transported over long distances should be in air-conditioned or refrigerated vans to keep them cool until delivery at the processing centre.

Processing should start immediately after harvesting and transporting the leaves to the processing centre. Strip all the leaflets from the leaf petiole. This can be done directly from the branches, if the leaves have not been stripped off the main branches before transportation.

Leaflets are washed in troughs using clean potable water to remove dirt. Leaves are again washed in 1% saline solution for 3-5 minutes to remove microbes. Leaves are washed again in clean water. Troughs are drained after each wash and leaves are finally washed with fresh and clean water only. Leaves are now ready for drying. Leaflets are spread on trays made with food-grade mesh and are left to drain for about 15 minutes before taking them to the dryer.

Leaflets are spread thinly on mesh tied on racks or tables in a well ventilated room. This room should be insect, rodent and dust proof. Air circulation can be improved by using ceiling and floor level vents protected with a clean filter to keep the sun and dust out. It is possible to use a fan, but the air of the fan must not be directly oriented towards the leaves, as it can increase contamination with germs in the air. The temperature range of the room or shaded room is kept from 35c to 55°C. It is advisable to turn the leaves over at least once with sterile gloves to improve uniform drying. Leaves should be completely dry within a period of maximum 04 days. The loading density should not exceed 1kg/m2. Leaves may also be dried in electric hot air dryers by keeping the temperature range from 45 C to 55C. The temperature should not exceed 55C and leaves should be dried until their moisture content is below 10%. The loading capacity should not exceed 2.5 kg/m2.

Dry leaves are then milled or grinded using a stainless steel hammer grinder/ mill or impact pulverizer. The leaf powder is then sieved with a stainless steel shieving & grading machine to get fine or very fine powder and then the fine or very fine powder is mixed with other ingredients in a stainless steel ribbon blender/mass mixer.

Moringa leaf powder strongly attracts moisture and the product can reabsorb humidity during or after grinding/milling. Moringa leaf powder, therefore, should be dried for about 30 minutes at about 50 C to reduce moisture content considerably below 7.5%. finally grinded/milled fine or very fine powder makes it easier for bacteria to penetrate the particles. All persons involved in packing of moringa leaf powder must ensure that, while on duty, personal cleanliness and hygiene are maintained. Personal protective equipment (PPE) such as head caps, nose masks, disposable gloves etc. must be used at all times.

The temperature and humidity must be controlled in the packaging room to avoid rehumidification of the product. After drying, the powder is left to cool and packed into clean, single use polythene bags and sealed. This is enclosed in a second polythene bag and heat-sealed to maintain freshness and dryness prior to further use. The bags should be stored in a cool and dry place. Moringa leaf powder or product should be packaged in clean, dry and opaque containers made of materials that do not affect the quality of the product. Each package must be properly sealed to prevent content leakage as well as moisture absorption.

Each package or packet of moringa leaf product must be legibly marked with the following information:-

Name of product,

Net content,

Name and address of manufacturer/producer,

Lot/batch identification number,

Instructions for use,

Production/packing date,

Nutritional information etc